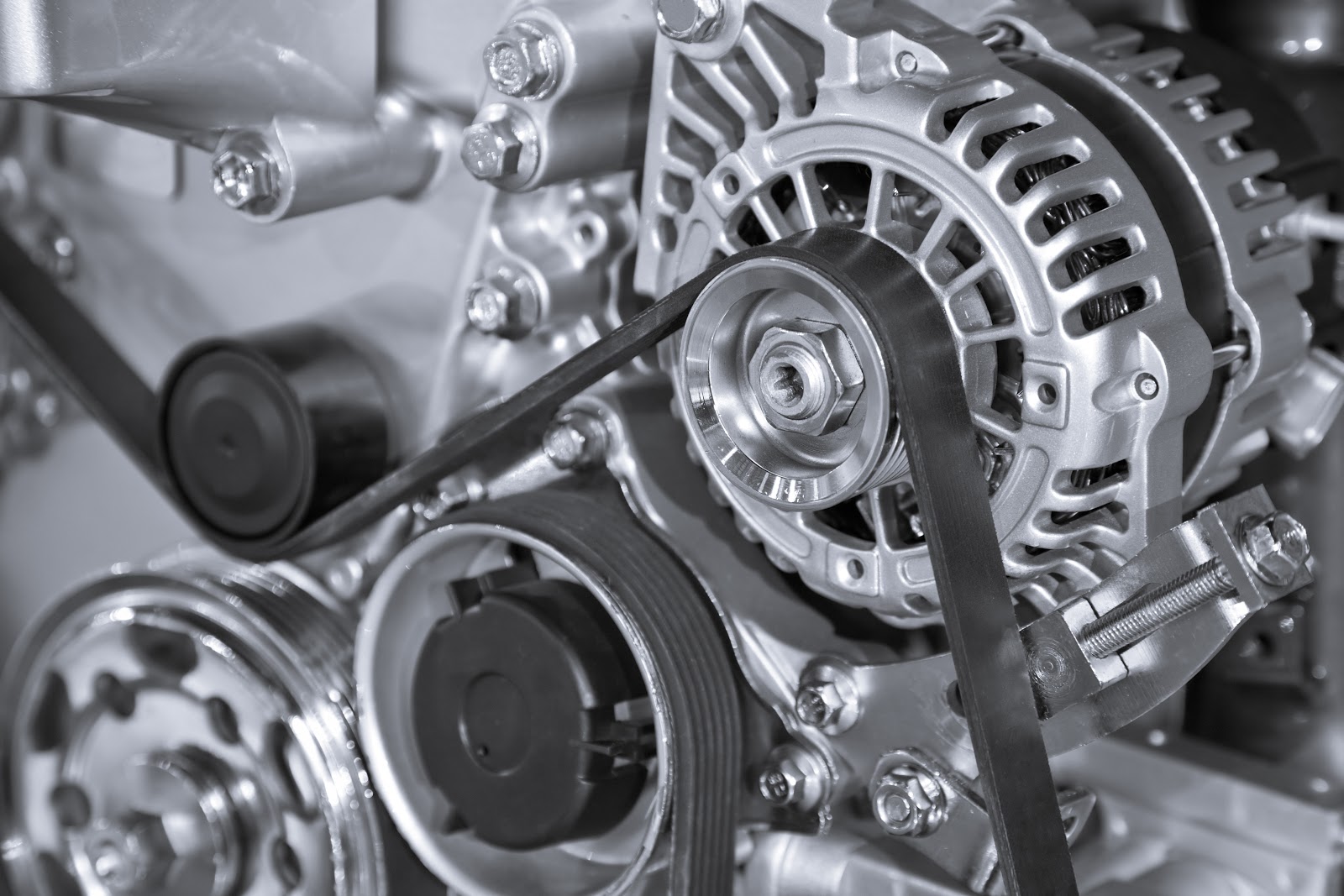

A v-belt is a versatile machine part used to impart power between many wrinkled pulleys or heaps. They are depicted as belts having a trapezium cross-portion. V-belts are the most by and broadly used belt drives since their estimation makes them wedge solidly into the part as the strain is extended. As the correas trapeciales wedges into the region, the crush between the external layer of the belt is developed, allowing high powers to be imparted.

The extended scouring limits the lack of power through slippage. Before going further into v-belts, knowing a blueprint of belt drives is indispensable. Belt drives are machine parts that convey power between no less than two turning shafts, by and large with equivalent hatchets of insurgency. The correas trapeciales hover over pulleys affixed to the driver and follower shafts. These pulleys are set at a certain distance to make a hidden strain on the belt. At the point when latency, the disintegration makes the belt handle onto the pulley.

The turn of the driver pulley grows the burden on one side of the belt, making a tight side. This near side applies an irrelevant capacity to the follower pulley. Force is then applied to the decided shaft. Converse, the right side is the breathing space side where the belt experiences less pressure. There are numerous sorts of belt drives used today. The earliest belt drive uses a level belt delivered utilizing cowhide or surface. Level belts work adequately in low-power applications like farm stuff, mining, and logging.

At higher burdens and speeds, they will, for the most part, slip on the external layer of the pulleys and move out of the pulley. Another early belt drive is a rope drive delivered utilizing cotton or hemp. Rope drives are used on two pulleys with a V-formed groove. This handled the issue of moving out of the pulley enabling belt drives to be used over immense distances. A short time later, this was shaped into round belts which are delivered utilizing elastomeric materials like flexible, nylon, or urethane. The improvement of these elastomeric materials moreover brought the progression of belt drive development.

Belts like v-belts, ribbed belts, multi-groove belts, and crankshaft belts were made to handle the issues of past belt drives. Since belt drives rely upon scouring to stay aware of coupling with the driver and ally pulleys, paralyzing and over-troubling can be scattered by allowing the belt and pulley surfaces to slip from one another. This holds extravagantly high drives away from being imparted to driven parts preventing damage to the machine. Belt drives don’t respond, aside from driving rod belts. The surfaces of the belt and pulleys contact during movement.